I follow solar tech because small improvements add up to big savings. Today’s panels are already cheaper and more efficient than a decade ago — but the real story is what’s coming next. New cell chemistries, smarter electronics, better storage, and recycling will change how much energy a rooftop or field produces, how long systems last, and how quickly you recover your investment. In this post, I’ll walk through the most important future solar panel technology trends, back them with recent data, and explain what they mean for Pakistani homeowners, businesses, and installers.

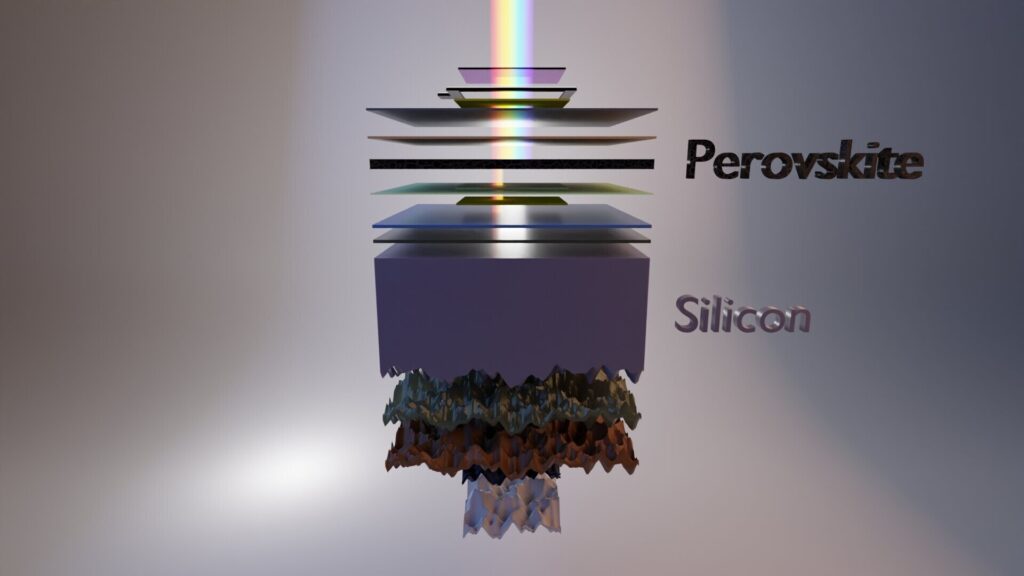

1. Tandem cells and perovskites — the big efficiency leap

Researchers and manufacturers are racing to put perovskite–silicon tandem panels into production. Tandems stack two light-absorbing materials to surpass the efficiency limits of single-junction silicon. Lab efficiency records have climbed rapidly; companies in Europe and China are moving from pilots to small-scale commercial runs. That matters because higher-efficiency panels produce more kWh per square meter — critical for rooftop-constrained customers.

What to watch: early commercial tandems and pilot factory announcements. If tandems reach mainstream supply, buyers will get more output from the same roof area — a direct boost to ROI.

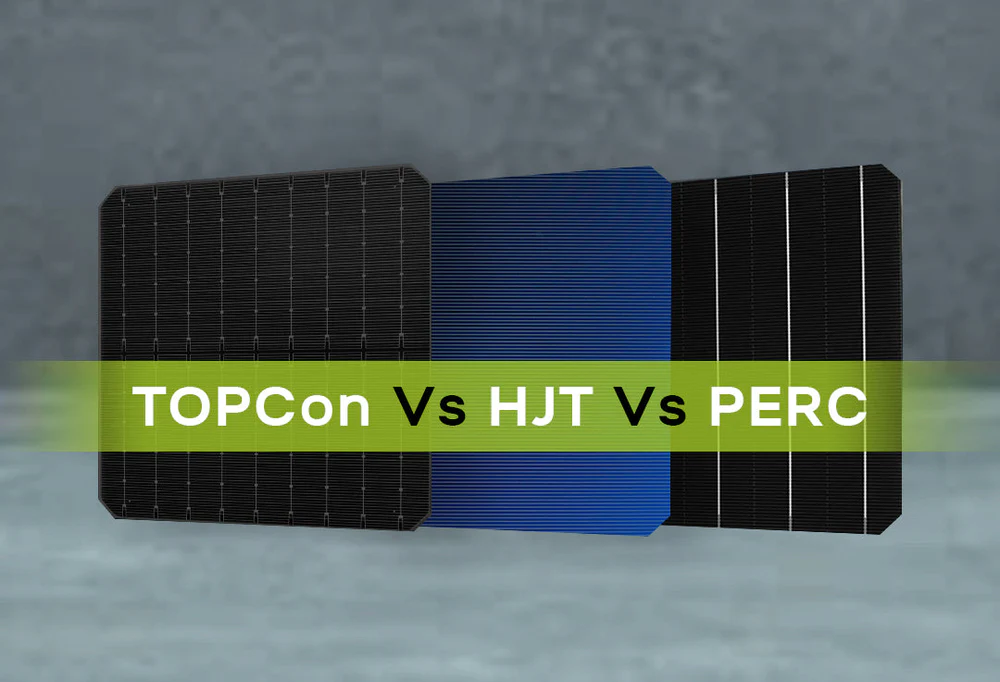

2. TOPCon and HJT — next-gen silicon without the hype

While tandems chase headlines, the industry’s immediate shift is toward improved silicon manufacturing like TOPCon and HJT. These cell types raise module efficiency and reliability while keeping production workflows similar to existing fabs. Market data shows TOPCon/N-type modules dominating recent shipments — a sign this is the practical near-term upgrade path.

For buyers: expect mid-term price/efficiency improvements from TOPCon — better output with familiar warranties and supply chains.

3. Bifacial modules + single-axis trackers — more energy per MW

Large projects and many commercial sites are combining bifacial panels (which harvest reflected light from the rear) with single-axis trackers that follow the sun. Studies and industry reports show combined annual yield uplifts typically in the 15–30% range compared to fixed, monofacial arrays — a powerful lever to lower levelized cost of electricity (LCOE).

Simple example: a fixed array producing 1,000 kWh/year could deliver ~1,250 kWh/year with tracker + bifacial gains — a 25% boost that shortens payback materially. Think of it as squeezing extra juice from the same panels.

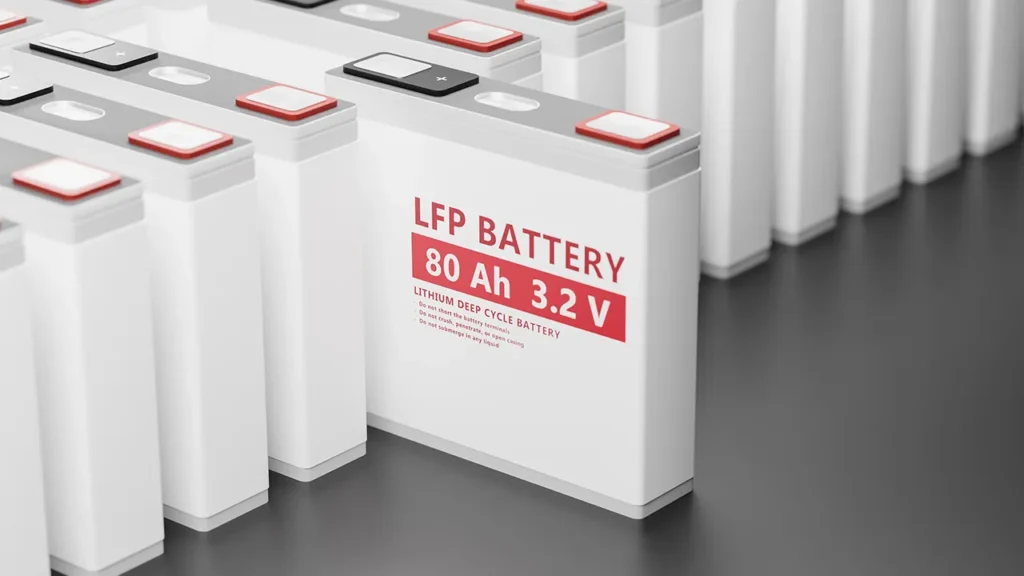

4. Storage chemistry shift — LFP becomes standard for resilience

Battery tech is converging on lithium iron phosphate (LFP) for stationary storage because of better cycle life, safety, and cost stability. International reports show LFP taking a dominant share in recent years — a trend likely to continue as LFP supply chains scale. For households and businesses, LFP means less frequent replacements and lower lifetime cost.

Why it matters in Pakistan: frequent outages and rising evening tariffs make storage valuable — LFP lowers the long-term cost of adding batteries to a PV system.

5. Smart inverters, AI monitoring, and virtual power plants (VPPs)

Inverters are no longer dumb DC→AC boxes. Smart inverters provide grid services (frequency/voltage support), and combined with AI-driven monitoring, they enable predictive maintenance and fleet-level optimization. Virtual power plants (aggregated distributed resources offering grid services) are growing worldwide — a model that could monetize rooftop solar beyond simple bill savings.

Takeaway: Smart power electronics will increase revenue streams (demand response, VPP payments) and improve system uptime.

6. Circularity & PV recycling — cleaning up long-term costs

As installations scale, end-of-life PV management becomes essential. Recycling initiatives and circular manufacturing aim to recover glass, silicon, and metals to reduce embodied carbon and material costs. Industry programs and recycling plants are expanding, which will lower lifecycle costs and address environmental concerns as Pakistan’s solar fleet grows.

Practical point: insist on suppliers’ take-back policies and module materials transparency when buying today.

7. New form factors — BIPV, thin-film, flexible, and floating PV

Panels are getting thinner and more flexible. Building-integrated PV (BIPV) and thin-film modules open aesthetic and space-saving options: façades, pergolas, and curved roofs. Floating PV and agrivoltaics make dual use of water bodies and farmland — attractive where land is scarce. These form factors expand where and how solar can be deployed.

For Pakistan: floating PV over reservoirs and agrivoltaics on marginal plots could add capacity without competing for prime farmland.

8. Manufacturing, supply-chain, and localization

Global module manufacturing remains concentrated, but some diversification and localization efforts are underway. For Pakistan, the future of solar panel technology, dependence on imports has shaped rapid adoption; local assembly, recycling plants, and quality controls could stabilize supply and create jobs. Keep an eye on policy incentives that encourage local value addition and standardized warranties.

Market picture & data snapshot (what recent numbers tell us)

Pakistan’s uptake has been dramatic: recent reporting puts rooftop and distributed solar in the multi-GW range, with rapid imports of modules and rising share of solar in the grid mix. These market pressures are why technology and policy choices matter now — both for grid stability and for individual returns. If you’re planning a system, understand which technologies are readily available locally and which will arrive later via pilots and imports.

How to future-proof your purchase today (practical checklist)

- Prioritize panel efficiency and low temperature coefficients (TOPCon/HJT if available).

- Choose inverters with smart features and VPP compatibility.

- Design for bifacial gains if your site and albedo allow.

- Plan space for future batteries (LFP-ready designs).

- Ask suppliers about recycling/take-back and long-term warranties.

- Model economics with conservative yield and policy scenarios — include possible net-metering adjustments.

If you want a tailored road map for your rooftop or site, we can model yield scenarios using current module types, trackers, and storage options.

Expert takeaway & local relevance

Experts agree the near term will be dominated by improved silicon (TOPCon/HJT), smarter electronics, and cheaper LFP storage — while tandems and flexible PV move from R&D into early commercial use over the next few years. For Pakistan, where rooftops are at a premium and grid dynamics are shifting fast, these trends mean smarter designs: higher-efficiency modules, storage-ready inverters, and careful modeling of export credits vs self-consumption.

How does JS Technology help in the future of solar panel technology?

- We size systems using the latest module types and simulate bifacial/tracker scenarios.

- We offer hybrid solar+LFP storage packages and smart-inverter options.

- We advise on procurement clauses (warranty, recycling, take-back).

- We model multi-year cash flows under conservative policy scenarios so your system is future-proof.

Contact us for a free site assessment and a 5-year performance & ROI model that uses the latest tech options.

Conclusion — small bets, big effects

The future of solar panel technology is a chain of incremental improvements that together reduce costs and increase generation. Tandems may redraw the top of the efficiency ladder; TOPCon and HJT will lift baseline performance; bifacial + trackers and LFP storage will change project economics; smart inverters and recycling will reshape the lifecycle. For Pakistan, the choice today is not to chase every headline tech, but to buy wisely: favor higher-efficiency, smart-ready systems, and insist on transparent warranties and recycling pathways. That way, your rooftop stays valuable — not obsolete — as the next wave of solar arrives.

Thought-provoking close: Technology keeps shrinking the distance between sunlight and usable power. The smarter we build today, the less we’ll pay tomorrow — and that’s a future worth investing in.

Frequently Asked Questions

Q1: When will perovskite tandem panels be commercially available?

A1: Early commercial pilots and small runs are appearing now; mainstream volume depends on stability and scaling and will likely expand over the next few years.

Q2: Are TOPCon modules available today?

A2: Yes — TOPCon and other N-type silicon modules are already shipping at scale and make up a growing share of global shipments.

Q3: Do bifacial panels and trackers really increase yield?

A3: Yes — combined gains of 15–30% are common in many installations, lowering LCOE for utility and commercial projects.

Q4: Should I add batteries now or wait?

A4: If you need resilience or face high evening tariffs, adding LFP storage now can be cost-effective; otherwise, design your system to accept batteries later.

Q5: Will new tech make my panel obsolete?

A5: Not quickly. Quality modules with good warranties remain productive for decades. Future upgrades (batteries, smart inverters) can extend value without full panel replacement

Selected references & reading

- Perovskite and tandem progress: Ceramic Tech Today; C&EN coverage. The American Ceramic Society+1

- TOPCon market trends and module shipments: Infolink / Wood Mackenzie. infolink-group.com+1

- Bifacial + tracker analysis: IEA-PVPS report. IEA-PVPS

- LFP adoption trends: IRENA and industry sources. irena.org

- PV recycling and circular economy: NREL / industry reports. nrel.gov+1

- Pakistan market context and import surge: Reuters / REN21 snapshot. Reuters+1